XENON Experts Case Study

Scaling Precision: An ROI-Driven Transformation in Sensor Manufacturing

A leading global manufacturer of high-precision electronic sensors faced growing demands for quality, traceability, and process reliability—all while managing increasing product diversity and advancing miniaturization.

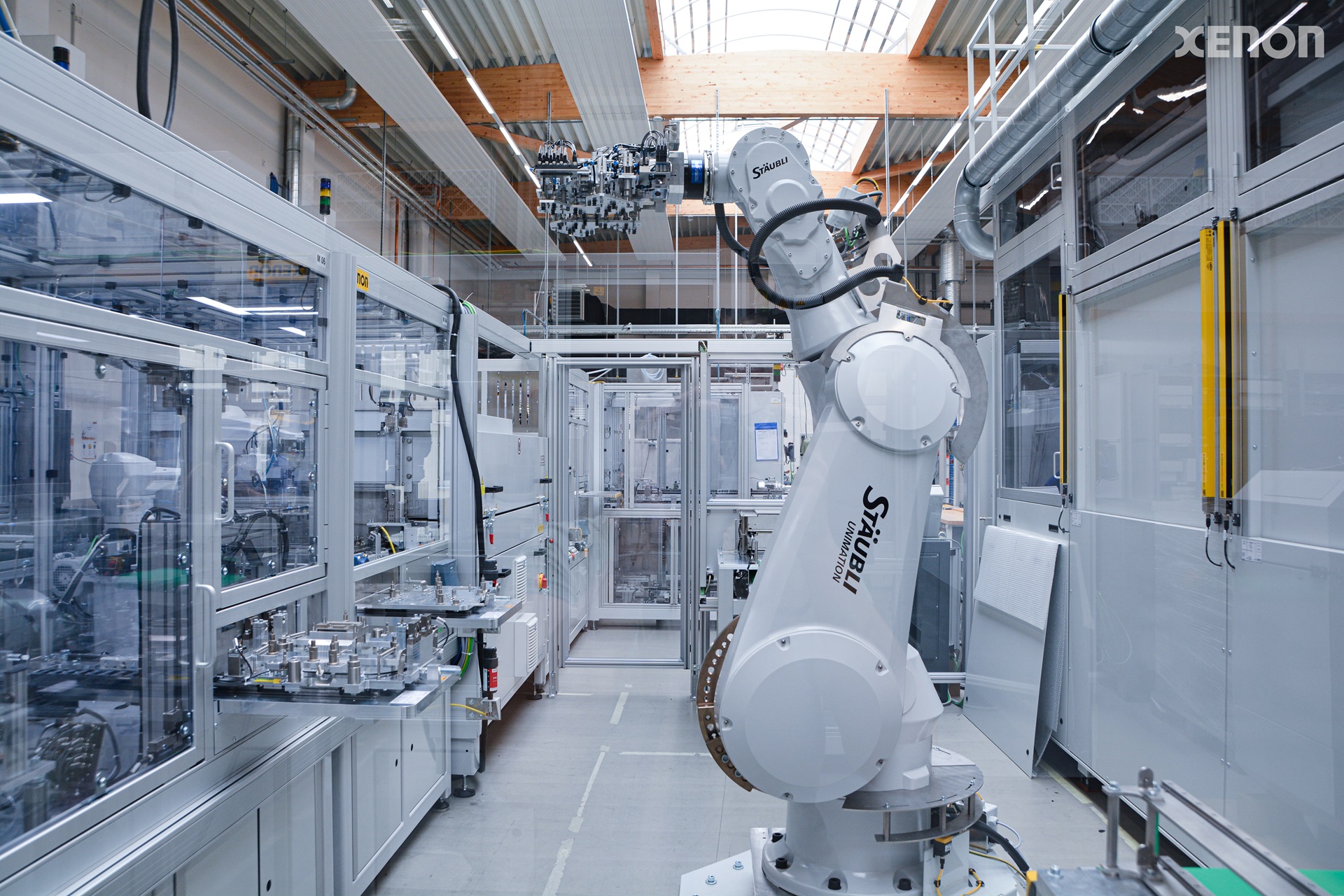

XENON developed and implemented a customized automation solution tailored to the complex requirements of sensor manufacturing. Key focus areas included:

- Cleanroom-compatible production processes

- Flexible handling of highly sensitive components

- High-precision calibration and testing technologies across the entire value chain

The result: a modular and scalable system concept covering everything from material feeding, joining, and testing to fully automated packaging. The solution enables maximum process stability, reduced error rates, and real-time quality monitoring.

What you will learn

In this case study, you will learn how XENON helped a leading global sensor manufacturer to:

- Reduce analysis times for quality deviations from weeks to minutes

- Identify critical production batches (lots) early on and avoid bottlenecks

- Visually display batch data and route histories for quick root cause analysis

- Increase production yield measurably while improving traceability

- Implement a scalable automation solution that meets cleanroom requirements and supports high product variety

Download Your Sensor Automation ROI Analysis Case Study

Would you like to know more?

We will be happy to answer your questions.

Just give us a call.

Your Contact

Daniel Schümann

Sales Manager