XENON Experts Case Study

Scaling Precision: An ROI-Driven Transformation in Sensor Manufacturing

A leading global manufacturer of high-precision electronic sensors faced growing demands for quality, traceability, and process reliability—all while managing increasing product diversity and advancing miniaturization.

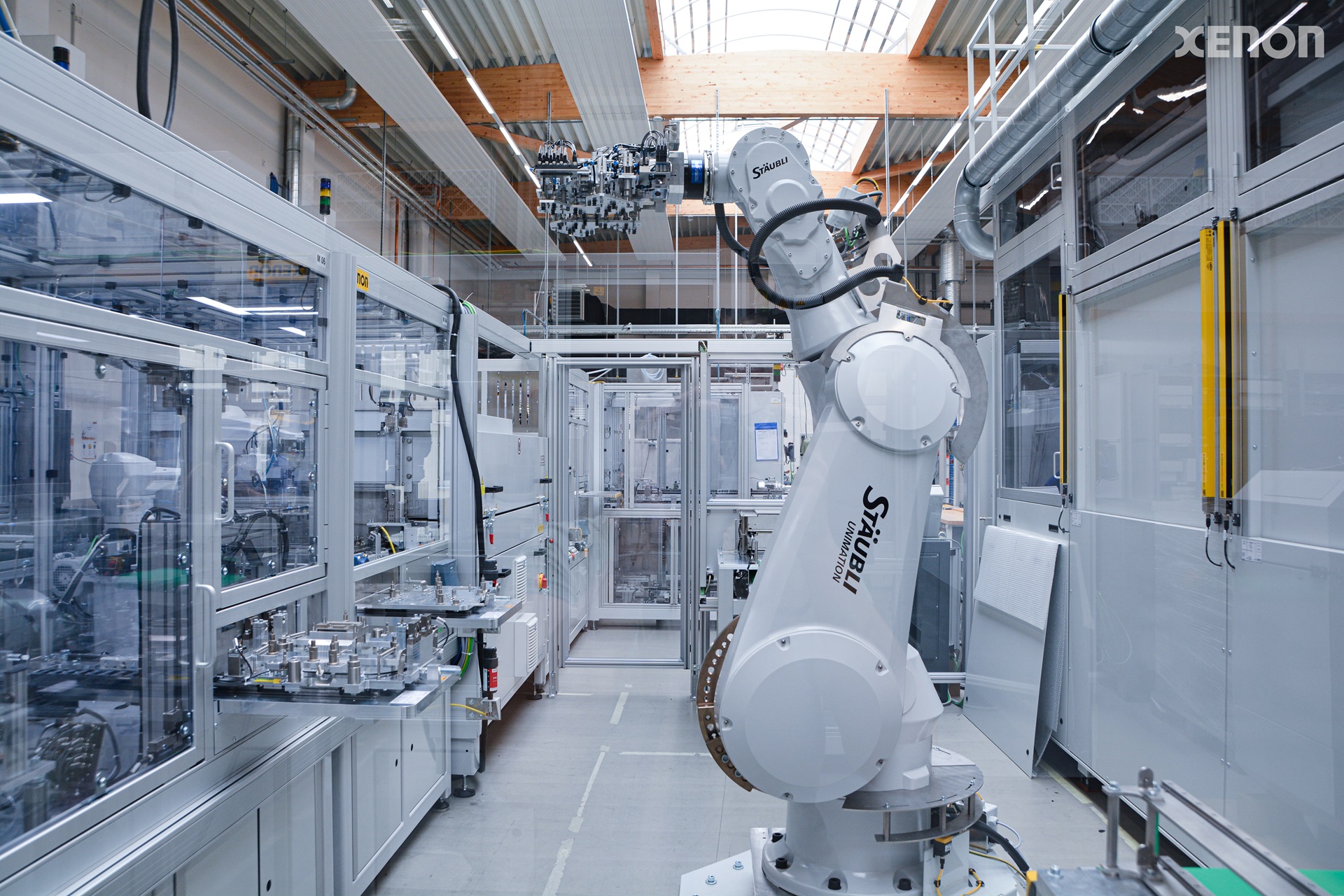

XENON developed and implemented a customized automation solution tailored to the complex requirements of sensor manufacturing. Key focus areas included:

- Cleanroom-compatible production processes

- Flexible handling of highly sensitive components

- High-precision calibration and testing technologies across the entire value chain

The result: a modular and scalable system concept covering everything from material feeding, joining, and testing to fully automated packaging. The solution enables maximum process stability, reduced error rates, and real-time quality monitoring.

What you will learn

In this case study, you will learn how XENON helped a leading global sensor manufacturer to:

- Reduce analysis times for quality deviations from weeks to minutes

- Identify critical production batches (lots) early on and avoid bottlenecks

- Visually display batch data and route histories for quick root cause analysis

- Increase production yield measurably while improving traceability

- Implement a scalable automation solution that meets cleanroom requirements and supports high product variety